Mike Adjeleian was a 27-year-old student at the Rhode Island School of Design when he was electrocuted at a manufacturing plant during a school trip. Nearly 40 years later, Adjeleian is a family man, an industrial designer, and the mind behind the L’il Sucker, an innovative cup-holding technology.

The story of how it all came to be is one that still makes him emotional.

A student of industrial design, Adjeleian, a dual U.S.-Canadian citizen, was living in Rhode Island and attending a school trip about manufacturing processes.

(Sponsored)

Advanced Business Interiors (ABI) is Making Space Work in Ottawa

ABI’s journey began with a small team on Thurston Drive in 1989; four locations and almost 37 years later, Advanced Business Interiors is now one of the largest office furniture

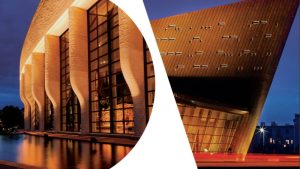

Iconic spaces, lasting impressions

The Canadian Museum of History and the Canadian War Museum offer more than beautiful spaces; they provide meaningful settings celebrating heritage, culture and design. An architectural landmark overlooking Parliament Hill

“I was standing next to the CEO in the plant and asked if they ever had accidents, because there weren’t any hard hats, boots, or safety procedures. He said no,” recalls Adjeleian. “Not a millisecond later, the electricity went through my left leg and blew a hole through my chest on its way out.

“I was dead to the world.”

Adjeleian took a few years off from his studies to recover, though he says he’s still processing the event to this day, and graduated in 1990. But the experience changed him, and his life, forever, he says.

“It feeds into my determination to survive, to succeed and to be a good person and conduct myself well,” Adjeleian explains. “Now I celebrate two birthdays: the date I was born, and Oct. 16, 1986, the day I returned to the world.”

As a new graduate, Adjeleian always had an entrepreneurial spirit and a calling to solve problems. After completing his studies, he moved home to Ottawa and rented a studio apartment in the ByWard Market. It’s where he invented his first product, but that was just the beginning.

A self-described “wannabe cop,” Adjeleian’s first invention was inspired after he saw a police officer drop a flashlight when reaching for a driver’s details at a roadside stop. The next day, he heard on the news that a police officer had been killed.

“I have no idea if the two events were connected. But it felt important to me and I thought about what I’d seen and how I could make things safer,” he explains. “That’s all industrial design is … it’s looking at an operational sequence, getting from point A to point B, and removing steps in between to make it better, simpler or safer.”

Adjeleian was experimenting with neoprene as he tried to find solutions that could assist law enforcement and was “messing around” with the material when the idea for L’il Sucker took hold.

“I was trying to find a product that would prevent glare off the glass with a flashlight, so I was up at the window with one of those big law enforcement flashlights,” says Adjeleian. “The material just sucked the flashlight right out of my hand and stuck it to the window, and that was my ‘eureka!’ moment.

“I immediately grabbed a canned drink and the wheels were already turning, and that was how L’il Sucker was born.”

A L’il Sucker product today is a donut-shaped piece of neoprene with a rubber-like bottom. When placed around a can, bottle or cup, the fabric creases around the object and fuses to the tabletop underneath, creating a nearly unbreakable seal.

A L’il Sucker can be used on counters or desks or most any other surface, including kayaks, paddleboards, coolers, ATVs, or vehicles. Nearly any smooth surface will work, and the seal can withstand up to 200 lbs of pressure. The result is an non-spillable, untippable cup holder that seems to have been embraced by everyone from boaters and campers to tradespeople since it first hit the market more than 20 years ago.

Part of the product’s success, Adjeleian says, is its unique branding. Adjeleian was working with a friend to name the product and says both were out of ideas when they each independently came up with the name “L’il Sucker.”

“We showed each other the name we had thought of at the same time, and it was the same name,” he laughs. “I knew then that that had to be its name.”

Lil Sucker Products now includes Magneato, a magnetic drink holder, a variety of L’il Sucker sizes, as well as beverage insulators. All are designed, manufactured and shipped out of Kemptville.

“I’ve often been asked, ‘Why Kemptville?’ and I’ve asked myself the same,” says Adjeleian. “The truth is, I’m a dual citizen, but my home is Ottawa. When it started, my wife worked in Ottawa, my son was born here, I have a cottage nearby, and it’s close to the border.”

Kemptville’s proximity to the United States is a definite plus, he says, because Americans make up 90 per cent of L’il Sucker’s market.

“I’m not just the designer, because I had to become a logistics expert, there’s a lot to learn and I’ve pretty much got it figured out now.”

L’il Sucker Products ships out of Ogdensburg, N.Y., and through Amazon.com, which is currently the product’s biggest sales channel. Despite “organic” growth over the past few decades, Adjeleian says the product still has a “wow factor” that “sucks” customers in.

Currently, Adjeleian is looking to make more inroads into the Canadian market, with L’il Sucker to be launched on Amazon.ca next week and talks with Canadian retailers ongoing.

“The Canadian market is different, so we’ll see,” says Adjeleian. “They weren’t taking that leap of faith years ago, but maybe they will now.”

L’il Suckers are dye-cut and entirely customizable with a variety of colours and patterns to choose from, which has also helped with marketing. Adjeleian says he has worked out branding deals with companies like YETI, as well as created Suckers with promotional branding for various companies.

Another branding success for Adjeleian was the creation of a “family pack,” which features a variety of L’il Suckers in all sizes to hold everything from a can of paint to a nail polish bottle.

The operations in Kemptville employ up to 12 people, depending on product demand, and are capable of dye-cutting 1,000 L’il Suckers and printing 800 each hour. At full capacity, the facility could manufacture 5,000 products per day, with a maximum of about 8,000.

In 2022, Amazon alone accounted for up to $50,000 in L’il Suckers each week, Adjeleian says, for orders that were completed within a few days for a quick turnaround.

But despite L’il Suckers’ production potential and ongoing success, Adjeleian says he’s hoping to slow down in coming years – at least in his role within the company.

“The future is, ‘Mike is getting older,’” laughs Adjeleian. “I want to work smarter, not harder, and work on the business instead of in the business.”

Next steps will involve hiring an office manager to oversee most operations, Adjeleian says, and “grow what we’ve got.” After all, he says, “as much as I wish I could, I can’t clone myself.”

“I’d love to see it grow into a household product, because there are so many good opportunities,” he continues. “But I need to do more design, I need to be creative, because there are so many more things I can do with this.”

-

-

-

-

The L'il Sucker is sealed when the material creases around the bottom of the beverage.

The L'il Sucker is sealed when the material creases around the bottom of the beverage. -

Even when Mike Adjeleian pulls on the L'il Sucker with all his strength, it doesn't budge...But the table starts to lift off the ground.

Even when Mike Adjeleian pulls on the L'il Sucker with all his strength, it doesn't budge...But the table starts to lift off the ground. -

Lifting the edge of the L'il Sucker will break the seal so the beverage can be moved.

Lifting the edge of the L'il Sucker will break the seal so the beverage can be moved.