Hold on to your hats: Ottawa-based MDS Aero Support dropped by for this week’s edition of Techopia Live, where vice-president of business development Joe Hajjar shared the high-powered details of what the local firm is planning for the world’s largest engine test facility for customer Rolls-Royce.

Slated for completion in 2020, the 1.85-acre facility in Derby, England will push “the art of the possible,” Hajjar told Techopia Live. The test cell, as it’s called, will be home to Rolls-Royce’s next-generation jet liner engine, a powerful, 12-foot diameter gas turbine.

“They want to put it through its paces. They want to test it, they want to break it, they want to push the envelopes of testing to develop the data they need to produce a better product,” he said.

(Sponsored)

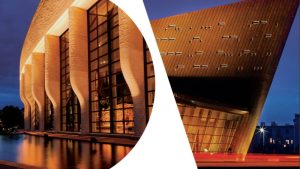

Iconic spaces, lasting impressions

The Canadian Museum of History and the Canadian War Museum offer more than beautiful spaces; they provide meaningful settings celebrating heritage, culture and design. An architectural landmark overlooking Parliament Hill

The story behind Glenview Homes’ 2025 GOHBA award-winning Reveli floor plan

When Glenview Homes’ Design and Drafting Manager Eno Reveli sat down to design a new production floor plan, he wasn’t thinking about awards or show homes. He was thinking about

That’s no easy task. The test cell will have to run Rolls-Royce’s engine indoors at full power as though it were about to lift a jet off the runway. The turbine will be suspended from the ceiling, surrounded by equipment that will be able to restrain the engine’s powerful thrust while also measuring its performance.

One of the ways the facility will test the engine is by throwing debris at the spinning blades and intentionally breaking parts of the device to see how the turbine would react. While all of this is going on, Rolls-Royce will also be x-raying the engine, necessitating extra layers of security throughout the facility.

MDS’s Ottawa engineers are responsible for making sure every aspect of the facility is up to the job. The 250-person aerospace firm has not only made Ottawa its home, but Hajjar noted that half of the company’s engineers are graduates of Carleton University.

This team of engineers has worked with Rolls-Royce’s crew for the past year to establish a working concept for the test facility. Also on board was MDS’s long-time partner the National Research Council, which helped to construct scale models for the facility.

Hajjar said that because a test cell of this scale has never been constructed before, MDS had no existing data to draw on. NRC’s labs helped to ensure that what MDS and Rolls-Royce are attempting is, in fact, possible.

“You’ve got to spend a lot of time and money convincing yourself that you’ve got it right,” Hajjar said. “I think we do, and the future will tell us.”

The NRC isn’t the only Crown corporation that MDS has leveraged. The global firm has worked for clients in 27 countries, an international scope that Hajjar said wouldn’t be possible without the Canadian Commercial Corporation.

“Without CCC, MDS wouldn’t be in existence today,” he said.

The CCC helps Canadian companies to enter foreign jurisdictions with the support of its trade commissioners. These well-placed sources can help Canadian firms facilitate contract negotiations, connect them to supply chains and bridge cultural barriers, even going as far as to put Canada’s reputation behind a national company.

“They sit with a customer and say, ‘Canada will deliver this project to you,’ and they offer a sovereign guarantee that a Canadian company will perform,” Hajjar said.

To hear more about what MDS will be delivering to Rolls-Royce in the coming years, watch the video above.